Why the future of global business hinges on collaborative supply chains

The global supply chain, once an invisible backbone of business, has become a hot topic in boardrooms and headlines alike. From geopolitical instability to raw material volatility and ongoing labour shortages, the systems that keep goods moving around the world are under more stress than ever before. And while it’s true these challenges aren’t new, their increasing intensity and frequency are creating significant obstacles for organisations.

The message for business leaders is clear: traditional one-dimensional supply chains are no longer fit for purpose. To thrive in this new era, companies need to rethink their operations and put resilience and collaboration at the core.

The shift from isolation to integration

Historically, supply chains have operated in silos. Each participant, whether a supplier, manufacturer or logistics provider, managed its own data and systems. If they had tight collaboration with a supplier, it had little to no redundancy. That model worked when the world moved slower but with complexity mounting and customer expectations growing, it’s become a competitive disadvantage.

Take the global semiconductor shortage that crippled automotive production across multiple continents as an example. As chip supplies tightened, many automakers were forced to halt production. Without multiple sourcing options and synchronised data flows between those supplier options, contract manufacturers and OEMs, companies struggled to understand inventory levels, forecast availability or secure alternative sources. And the result? Idle factories, delayed launches and billions in lost revenue. It’s clear the root issue wasn’t just limited supply but was a breakdown in end-to-end visibility and communications.

This disconnect underscores an important truth in modern supply chains: your overall strength depends on the weakest link, which often lies in the gap between data and decisions. This is a gap that cloud-enabled collaboration is uniquely positioned to close.

Digital ecosystems as the new gold standard

What would happen if your top supplier went offline tomorrow? In a truly collaborative ecosystem, the answer doesn’t have to be chaos because people across the entire network can work together seamlessly. Building digital ecosystems where all partners, not just internal departments, can connect and collaborate in real time means nobody is left in the dark.

Secure cloud-based platforms built with role-based access for both internal and external collaboration are central to this transformation. They bring everybody onto the same page by allowing businesses to connect their systems, standardise operations and share immediate visibility into what’s happening on the ground across a complex network of suppliers and distributors. In addition to enabling faster decisions, these platforms make supply chains elastic, which means they’re able to flex and scale in response to changing conditions. Whether it’s ramping up production to meet unexpected demand or redirecting shipments during a regional disruption, agility becomes the norm rather than the exception.

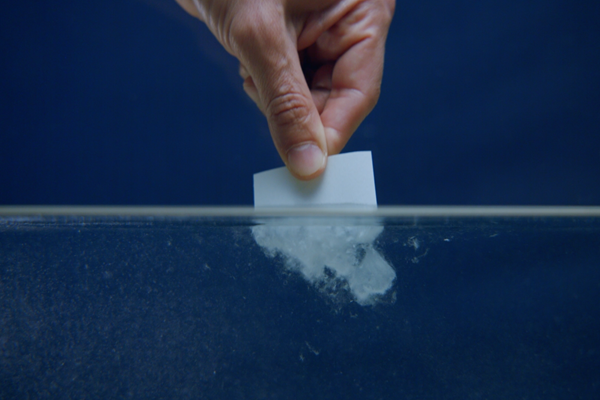

One often overlooked area where this has real-world impact is product identification. Inaccurate labelling can cause a multitude of issues including regulatory penalties, shipment delays and costly recalls. However, with a standardised and centralised labelling solution, companies across all industries can avoid those pitfalls while also improving compliance, time to market and customer satisfaction.

Consider Lubrizol, a specialty chemicals manufacturer, who achieved a 30 per cent improvement in compliance and efficiency by integrating its labelling with SAP, ensuring consistent data flow and faster market delivery. Similarly, Varian, a global medical device manufacturer, reduced product identification errors by 80 per cent and accelerated product approvals by integrating its labelling solutions across suppliers.

Bridging the digital-physical divide

But even with these successes, many organisations still struggle with a common disconnect: the difference between what’s documented in digital systems and what physically arrives on-site. A supplier may send an advanced shipping notice (ASN), but that doesn’t guarantee that what shows up matches what was promised. These mismatches can grind operations to a halt and erode trust throughout the value chain.

That’s where cloud-enabled collaboration becomes even more powerful. By tying together data from enterprise systems, logistics providers and smart devices such as barcode scanners or RFID readers, companies can validate and reconcile shipments in real time and before they hit a bottleneck, reducing errors, saving money and resources and improving overall supply chain efficiency.

Even more transformative is the ability for customers to define their packaging, labelling and delivery specifications digitally. When suppliers follow a unified digital playbook, goods arrive exactly as needed, eliminating costly instances of rework and manual intervention. That kind of straight-through processing is not just efficient but also a differentiator in highly competitive markets.

Scaling with confidence

One of the most underrated benefits of collaborative supply chains is how they support rapid expansion. Entering a new market or launching a new product line typically requires onboarding new partners and aligning processes from scratch, which can be a time-consuming and error-prone process.

However, when you’re operating within a connected digital ecosystem, onboarding can shift from taking months to just weeks or even days. New partners can quickly align with existing standards and systems, minimising disruptions while preserving consistency and compliance across regions. In other words, companies that invest in collaboration aren’t just reacting faster, they’re growing without sacrificing control or compliance.

Trust and accountability in a digital world

Technology may be the enabler, but people remain at the heart of supply chain success. Real collaboration demands more than shared systems; it requires shared values. That’s why transparency, accountability and open communication are critical.

Building long-term relationships with partners – and treating them as extensions of your own business – creates a culture where problems are solved faster and opportunities are seized sooner. When everyone is pulling in the same direction, the entire network becomes more resilient and responsive.

Embracing the next era of supply chain innovation

The future of supply chains is not just digital, it’s collaborative. As the global business environment becomes more interconnected and unpredictable, companies that embrace this mindset will have a clear edge. They won’t just survive disruption but use it as a catalyst for innovation and growth.

Learn more about modernising product identification across your supply chain here

Jim Bureau, President & CEO, Loftware

Business Reporter Team

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543