Major innovation brings a new level of sustainability to PET bottle recycling

Sponsored by SIPA

Around the world, there is now general agreement that the only possible development model capable of delivering a “zero waste” future to the world is the Circular Economy. Today, however, there are only a few cases of closed-circuit systems that can take a material that has reached the end of its originally-intended useful life, and make it new again, without generating more waste.

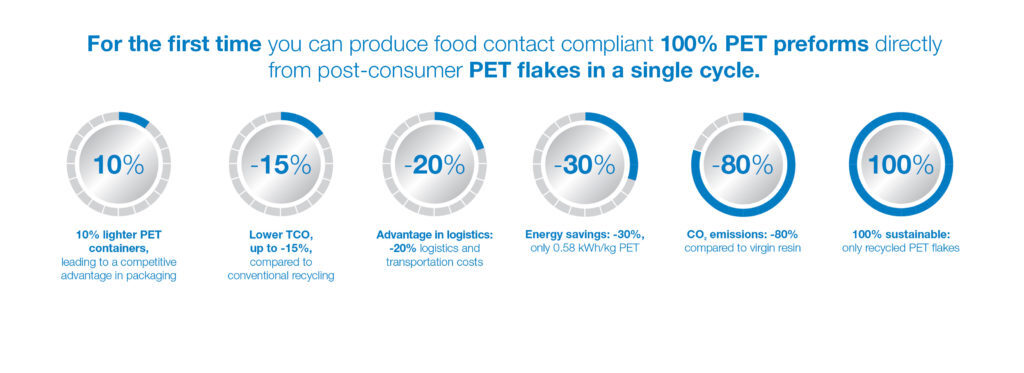

XTREME Renew is capable of using almost 30% less energy than a conventional PET preform production system; CO2 emissions are almost 80% lower. Compared with traditional systems producing rPET containers, the emissions reduction is around 18%. In addition to this, XTREME Renew has a lower requirement on warehouse space that can amount to as much as 20%.

XTREME Renews starts with EREMA’s Vacurema technology, which decontaminates and removes moisture from the flakes under vacuum. This technology uses less energy than alternative systems. In addition, it improves the colour of the processed material and keeps levels of acetaldehyde (a degradation product that can affect taste of bottled liquids) very low. The Vacurema system also creates a highly homogenous melt, even if input material has variable viscosity.

In conventional PET recycling systems, the extruder processing the bottle flake converts it into granules for processing at a later stage. This involves cooling the melt into a solid, cutting it up, drying it, and then later remelting it – processes that all require energy. But in the XTREME Renew process, the Vacurema extruder is connected directly with SIPA’s XTREME preform production unit, eliminating all of these steps.

The advantages do not stop there: XTREME uses a highly innovative extrusion-injection-compression moulding process to create ultralight PET preforms that perform just as well as conventional injection moulded preforms that weigh more.

Containers produced from the preforms boast a high level of aesthetics, thanks to the elimination of an entire melting process that could otherwise cause yellowing in the resin. XTREME Renew allows for bottle blowing to be carried out directly in-line with the production of the preforms, providing even more energy savings in preform cooling and reheating. Also, having separate preform and bottle production operations provides more flexibility for processors.

XTREME Renew technology is unique in its ability to produce top-quality bottles, suitable for food contact, directly from flakes of post-consumer waste, in a single heat cycle.

"Social responsibility is the basis of a company’s mission,” Zoppas concludes. “Combining environmental sustainability and economic development is possible. Businesses need to help deliver a better world for future generations, and that is just one more reason why we developed XTREME Renew. "

For more information please click here.

by Gianfranco Zoppas, President, Zoppas Industries

SIPA: the PET specialist

SIPA has been designing, manufacturing, and selling a wide range of technologies for the production, filling and packaging of PET containers for some 30 years – containers that are used for foods and beverages, cleaning products, cosmetics and pharmaceuticals. Based in Vittorio Veneto, Italy, the company employs more than 1100 people, creating a turnover (2019) of €220 million. SIPA has 17 sales branches, five production facilities (three sites in Italy, one in Romania and one in China) and 30 post-sales service centers for the provision of technical support and spare parts. It has installed 7,200 systems in almost 150 countries. Around the world, its customers number around 2600. Exports account for over 95% of the company’s production.

Business Reporter Team

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543